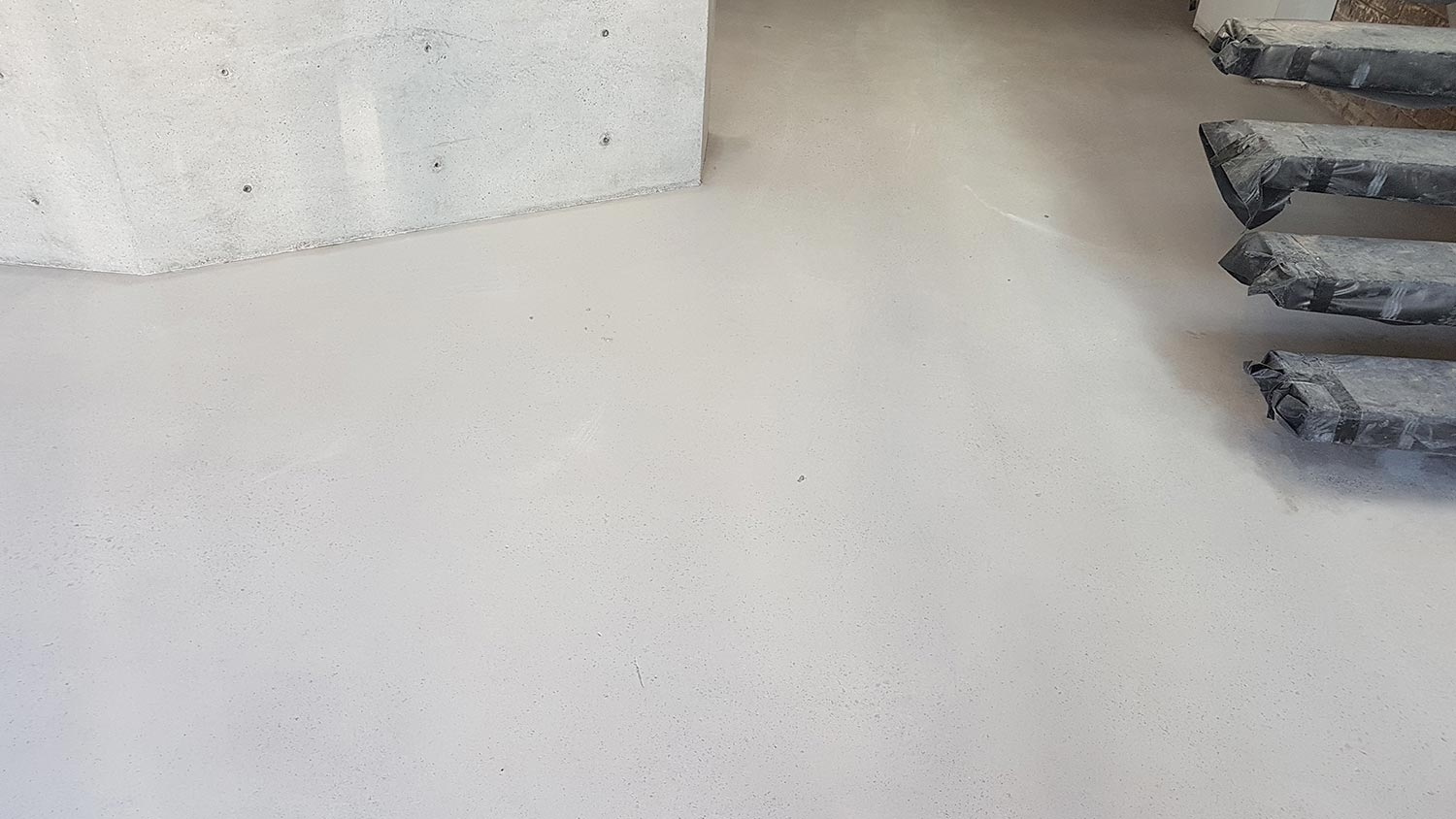

Perfect Concrete Care just completed Concrete Grinding works for A 2 Z Flooring Solutions Pty Ltd. The works included the concrete floor grinding of over 200m2. The client requested for exposing a specific course of concrete aggregate.

The Challenges

Concrete Grinding of 200m2 in Rozelle

Techniques Used:

- Concrete sealing to give the floor a beautiful finish

- Concrete Grinding of 200m2

Techniques Used:

Our team members first met with the client representative to discuss their requirements. Then, they assess the best plan of action to carry out the work. The client was looking for a very particular grade of concrete aggregate to be exposed in this case. So, firstly our team members used the Hilti DG150 hand grinder to expose a small part of the aggregate on the floor to ensure the client was happy with the result.

Once the client was happy with the level of the aggregate to be exposed then our team members inspected the site. And then they marked any blemishes on the floor, nails, or any objects that would affect our larger grinder. They marked these with spray paint to be carefully grinded with our Hilti DG150 hand grinders later.

We established all the equipment on site and began to set up. Our team members firstly installed new diamond shoes on the grinder to ensure a smooth and accurate finish. They then run power and set up our Tyrolit Dust Vacuum to ensure keeping the site as dust free as possible.

Once our team members were all set up and ready to go without HTC 650E Classic Grinder then we began the first pass of our grinding process. While one of our team members was working on the HTC Grinder, our other team members proceeded to work on the detail around the edges with the Hilti DG150 grinder.

Once we finished our first pass, we then consulted the client to ensure he wanted to expose more aggregate. Then we began our second and final pass, this exposed the correct amount of aggregate for the client.

We then began the clean-up process where we use our Hilti Dry Vacs to clean the area of all dust before we applied our sealing solution. The area was completely dusted-free. Then we proceeded to apply the first coat of our sealing solution. We then returned the next day to apply our second coat of sealing solution.

The Result:

The client was happy with how efficient our team members were. Also, with the outcome of the finish

- Client

A 2 Z Flooring Solutions - Location

Rozelle, Sydney - Duration

April 2017