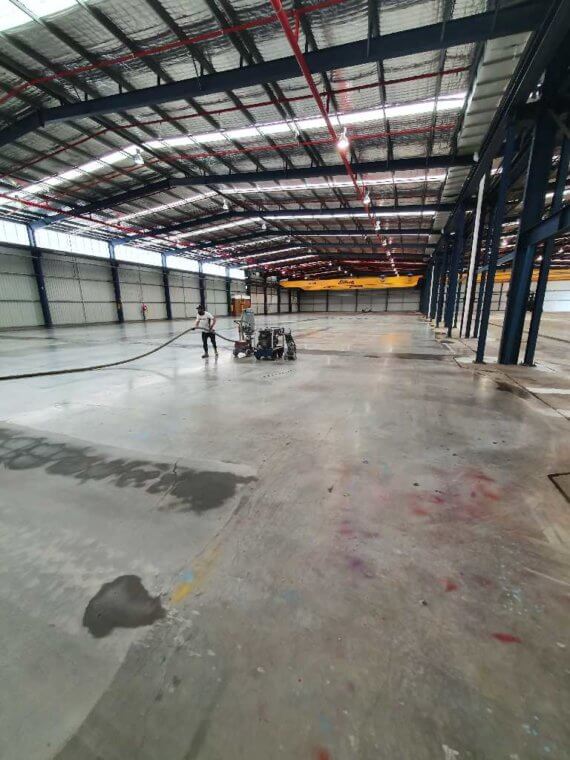

Perfect Concrete Care was engaged for the refurbishment of the flooring and walls in a factory in Ingleburn.

Firstly to start the grinding process we completed 2 passes over the slab with 20/25 low grit coarse diamond shoes. This is to cut into the concrete slab to remove all existing paint and membranes on the slab. This is also to prepare the slab for sealing.

The equipment Perfect Concrete Care used to carry out these works was one of our largest grinders the HTC 650 HDX 3 phase variable speed 18 feet floor grinder along with a Makita 5” hand grinder. The other equipment is a small tyrolit 270-floor grinder for detailing and edging works.

Throughout the grinding process, we removed approximately 500 bolts from the slab. After that, we infilled them with specific grout to cover them up.

After all the paint and membrane had been removed and holes refilled. We used large scrubbers to clean the warehouse floor and walls, cleaning off existing rust, dust, and any excess paint on the slab. This was the last stage before sealing.

The final stage of this job was sealing up the slab with our penetrating sealer applying 2 even coats over the entire 1400m2.

We were able to complete all stages of this project in 20 business days.

- Client

- Location

Ingleburn - Duration

20 days