Huge amounts of dust are produced when cutting concrete which can easily be inhaled when it becomes airborne. As a result, anyone exposed to the dust might develop various health complications depending on the nature and amount of dust inhaled. As such, it is important to use effective dust control methods to reduce dust while cutting concrete and in turn, create a safer working environment. Safety being at the forefront of Perfect Group’s core values, Perfect Concrete Care consistently strives to ensure that the safest methods are being implemented at our projects.

What Is Concrete Dust?

Concrete dust is a by-product of concrete coring, cutting, sawing or grinding. This dust takes the form of tiny crystalline particles composed of a mixture of mortar, plaster, concrete, stone, and sand. Since these materials also contain crystalline silica, in most cases, concrete dust also contains small silica particles.

Types of Concrete Dust

There are two main types of concrete dust:

Silica Dust – Silica is a naturally occurring material that is present in a variety of building materials including mortar, concrete, sandstone, granite, and sand. The material is broken down into fine dust during drilling, grinding, or cutting.

Non-Silica Dust – Some construction materials, such as marble, limestone, and cement, contain little to no silica. As such, these materials do not generate silica dust. However, since they may be mixed with silica-containing materials during the construction process, they may end up producing silica dust.

What makes Concrete Dust harmful?

Due to the microscopic nature of the dust particles, concrete dust is easily inhaled, making its way deep into the lungs. Extended dust exposure often leads to serious health risks, including, silicosis, lung cancer, Chronic Obstructive Pulmonary Disease (COPD) and asthma.

Methods to Minimise Dust Emissions while Cutting Concrete

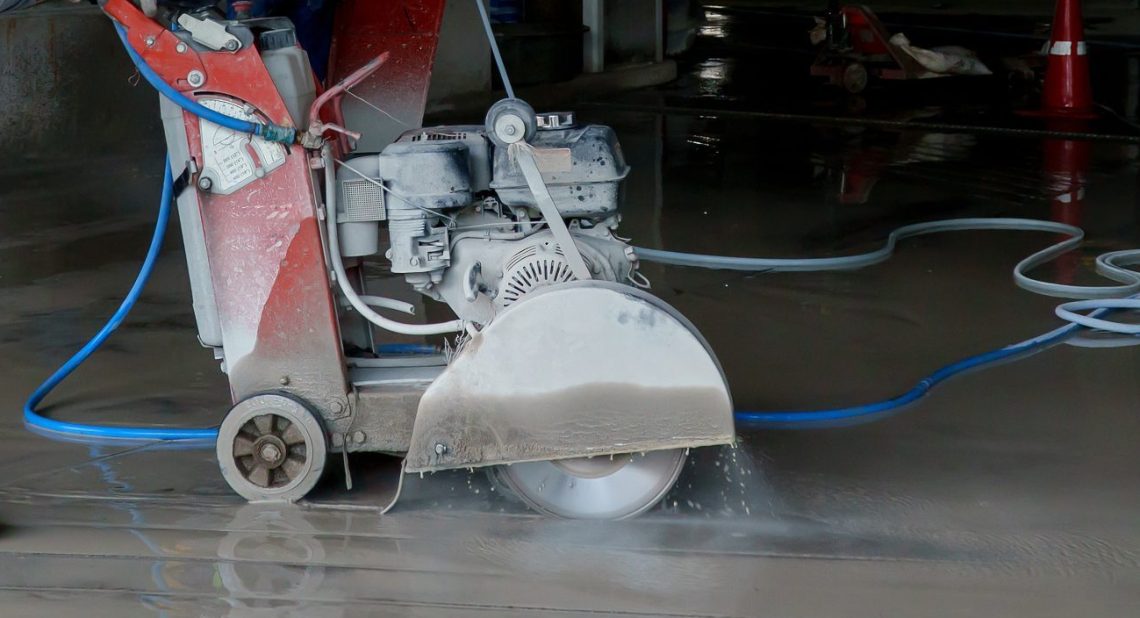

1. Use Wet Control Methods – Wet Saws or Water-Cooled Blades

You can reduce silica dust generation when cutting concrete by using wet cutting techniques. Wet systems hold water in pressurized tanks, which spray a continuous moisture stream onto the saw’s rotating blade as it cuts through the concrete. This process significantly lowers dust emissions and promotes faster dust settling.

It is important to use wet saws when concrete is being cut, particularly indoors, because it will reduce dust emissions being released into the environment. Wet saws are designed to reduce the amount of concrete dust created when they cut through dry surfaces like concrete by coating the blade with water during the cutting process. The water helps to keep the blade cool and lubricated which reduces friction between the blade and the surface being cut. This means that less pressure is needed for cutting because there’s no need to break through a crusty layer of hardened cement. This means that less dust and debris will be propelled into the air during your project.

When wet cutting concrete, verify that your water flow rate reaches at least half a litre per minute, as anything lower will impact cutting performance. You should also pressurize your water tank regularly to maintain proper flow rates.

2. Implement Dust Extraction Systems

Using dust extraction systems on the job site is another effective way to reduce dust levels when cutting concrete. These solutions include high-efficiency particulate air (HEPA) filters specially fitted to cutting tools to draw in concrete dust at the point of sawing, cutting, or drilling while preventing it from escaping the vacuum system.

There are two dust extraction systems that you can choose from : exhaust ventilation systems and high-powered industrial vacuums.

3. Wear Protective Equipment

When sawing concrete, it is important to wear a dust mask and goggles. Even when using wet cutting and dust extraction systems on the job site, you should wear respiratory protective equipment (RPE) to further prevent dust inhalation. When used in conjunction with other dust control methods, dust respirators prevent wearers from inhaling hazardous dust particles. This will protect your lungs from the harmful particles in the cement that could lead to an asthma attack or other respiratory issues down the road.

It is also important to wear eye protection in order to avoid getting dust and debris in your eyes which can cause eye irritation and impair your vision which impacts your ability to do your job properly.

4. Ensure Ample Ventilation

Sawing concrete is a high-energy process that produces a lot of dust and fumes. Therefore, if you are sawing concrete indoors, you should make sure there’s plenty of ventilation and airflow. This will help prevent dangerous particles from being released into the environment through the dust created while cutting the concrete and ensure you are not breathing in these pollutants which can potentially cause respiratory irritation. Concrete dust can cause Silicosis, a lung disease caused by inhaling tiny particles of silica. The most common form of this disease is called chronic bronchitis with fibrosis or Bronchiectasis. Both conditions are harmful to the lungs and usually develop in people who work around concrete for an extended period of time.

5. Cover surfaces with Plastic Sheeting

The cement can create a lot of dust and debris. Placing plastic sheets on surfaces where you are cutting will help prevent small particles of concrete making their way into places they shouldn’t be. Therefore, plastic sheeting not only makes it easier to clean up after the job, but it also ensures that the dust and debris does not cause any damage to other pieces of equipment or surfaces.

Furthermore, as mentioned earlier, concrete dust contains silica which can cause serious health problems if ingested later down the line after exposure. Placing plastic sheeting around the work area will help to ensure all traces of concrete dust are collected.

It is imperative to choose and implement the right methods to control dust while cutting concrete given the plethora of health implications associated with concrete dust. This makes assigning a professional company like Perfect Concrete Care for concrete cutting jobs particularly important.